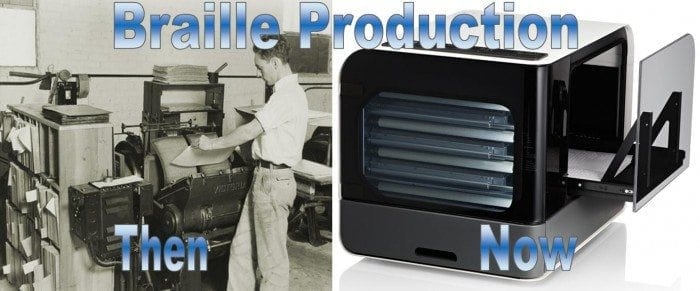

Embossed Braille vs. Pressed Braille

Published onWhich Braille Production Option Wins?

There are two methods to mass-produce braille documents; one is embossed braille and the other is pressed or plated braille.

Both methods can produce two sided braille called “inter-point” braille. This is made possible by offsetting the lines of braille from the front to the back of the page so they do not overlap each other and can be read for both sides.

Embossed Braille

Embossed braille is generated from braille printers called “embossers” which receive their files from computer software braille translation programs. The documents are transmitted to embossers that can produce small and large quantities of pages. This method allows more flexibility and can be produced on a variety of paper weights.

These documents are run on continuous paper that is burst apart into single sheets and bound with multi-ringed binding combs. The book can then be opened flat or folded back on it-self for easy use by the reader. Various cover materials can be used to give the document stability, a better presentation and keep them clean and dry in all environments. This type of binding is very practical for restaurant menus or for storage in brief cases and on shelving.

Embossed braille can also be bound in a folded magazine “saddle stitched” method. Usually this method is reserved for smaller documents for ease of reading. Braille embossers can be small table top units or large industrial size high-speed units that are floor standing models.

The savings is significant on the set-up and production labor because all the preparation for embossed braille is done on a computer and translates directly to the embosser as opposed to pressed braille where the translating is done on a computer and then a plate for each side of each page must be created and every page pressed individually.

Pressed Braille

Pressed braille may be faster in some cases although the cost for preparation is significantly more. Pressed braille is first produced through a braille translation program, but then a costly plate must be made for each side of each page. The plates are placed in large presses and require personnel to operate them through-out the entire process.

The paper is limited to a lighter stock and can only be folded “saddle stitched” with out protective covers. Since these documents are folded it is more difficult for the reader to use. The paper cannot be folded flat until you get toward the center of the document.

Pressed braille is not a flexible system and cannot be changed on the fly. If the customer has a change in a document after the plates are produced, new plates need to be made at the expense of the customer. If they want to make a change after the pages have been collated and stapled it would be almost impossible.

Storage and portability is more difficult with pressed braille documents and the life of the product is shortened because of the lack of protective covers and the lighter paper that is used.

And the Winner is…

It’s a common misconception that pressed braille is the only method for large volume braille runs; the emergence of high-speed embossers has put an end to depending on pressed braille. A high speed embosser can produce a thousand pages in an hour. Can you imagine a person pressing that many pages in that amount of time? It can’t be done. That reason plus so many more gives the win to embossed braille in my opinion.

Categorized in: Accessibility, Informational, Opinion, Technology

This post was written by

Comments are closed here.